Ensuring that a piece of rotating machinery will run smooth and stable is a key to ensuring long life and high reliability (unless you are trying to build a paint shaker). Xdot's rotordynamic analysis services can help you ensure that your machines will run smoothly. We have analyzed machines and machinery trains ranging from a 1200 MW nuclear steam turbine train with a rotating assembly weight of over 1.25 million pounds, down to rotors weighing less than a pound.

We use a combination of in-house analysis tools, along with Dyrobes to quickly and accurately perform all of the "standard" analyses, along with some things that are somewhat unique.

Our capabilities include:

Lateral Analysis

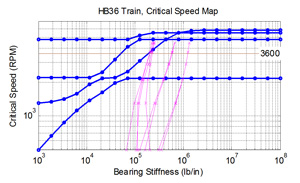

- Undamped critical speeds and mode shapes

- Damped critical speeds and mode shapes

- Stability analysis

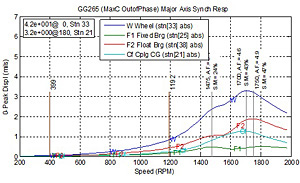

- Forced response due to unbalance, shaft bow, side forces, etc.

- Transient/nonlinear analysis for squeeze film dampers, blade loss, rotor drop, large amplitude responses

- Active magnetic bearings

Torsional Analysis

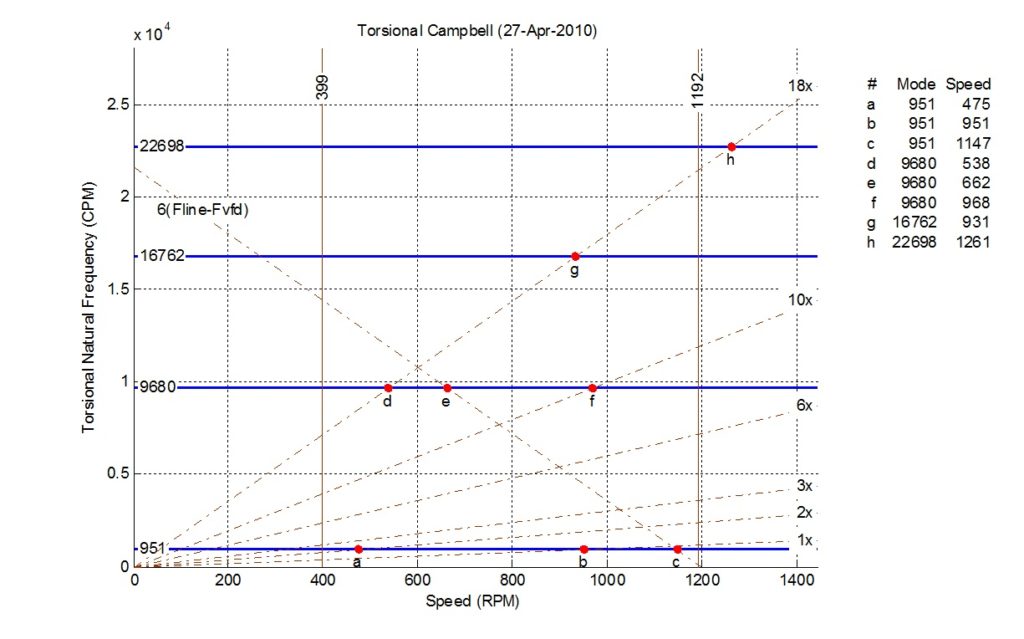

- Undamped critical speeds and mode shapes

- Campbell diagrams

- Steady-state response and fatigue life

- Start-up transient analysis

- Electrical fault transient analysis

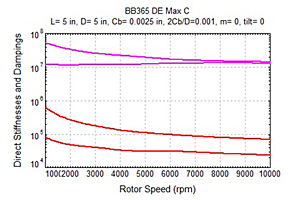

Bearing Analysis and Optimization

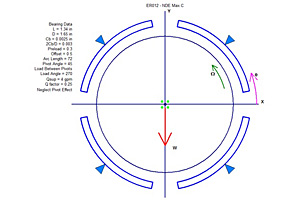

- Hydrodynamic (oil, water, etc.) fixed geometry bearings

- Tilting pad bearings

- Rolling element (ball) bearings

- Active Magnetic Bearings

- Foil Bearings

Unusual, complex and/or difficult analyses that others may not have the tools to do

- Two input planetary gearbox torsional dynamics

- Large parametric studies

- Coupled torsional lateral analysis