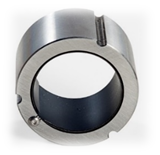

What was the customer’s key problem? Multiple customers needed bearings for small high-speed turbomachinery.

What was Xdot’s solution? Xdot has collaborated with multiple clients to determine the specific needs for new foil bearings, to develop custom state-of-the-art foil bearings, and to support bearing integration and machine development.

Xdot has successfully partnered with these types of customers to develop foil bearings to meet a range of requirements:

- Aerospace customer building a gas turbine that needed to operate in a hot environment (up to 1200 F / 650 C). Xdot can also support development for very cold environments (down to cryogenic temperatures).

- Customer in the consumer space with a product that required a long life at very high shaft surface speeds.

- Customers at a national lab and in the commercial distributed power industry who needed to use the process gas to eliminate oil and oil systems (Air, Refrigerants, Supercritical Carbon Dioxide, etc.).

- Aerospace DoD application to enable compact, lightweight systems.

At Xdot, we go beyond just developing a product and leaving it up to our customers to integrate into their systems. Our services include answering your design, assembly, integration, and testing questions. We continue to support you after product delivery, with consulting about interpreting test data. For interested customers, we can also support your own in-house development and production when your team is ready.